What problems are there typically in getting complete?

This, is often one of the final questions asked when starting a product conformity project.

If your design or product has the following issues;

Not designed to the required electrical standard / safety standard

Lack of correct over current protection for system /sub-assemblies

Use of sub-assemblies with no conformity information

Incorrect wire types or sizes

Grounding missing from parts of system

EMO/Interlock Function is inoperable, incorrect, or missing

System Nameplate needs correcting

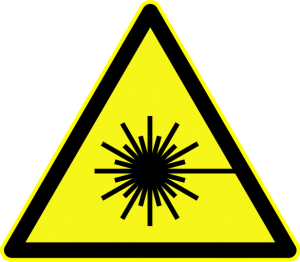

Lack of Safety Warning Labels, or incorrect formats

Lack of guarding and interlocking for hazards

Lack of required Documentation or

![images[8]](https://hightechdesignsafety.com/wp-content/uploads/2020/10/images8.jpg) Manuals

Manuals

Other uncontrolled hazards, heat, chemical, laser…

Safety devices not rated for use in a safety circuit

Controls or indicators wrong colors and placement

For more details please email me at Steve.Barcik@HTDS2.com